Reliability resources

Subscribe for updates

Customized RCA training options for your team

5 Why Template

Root Cause Analysis Technique

Doing a 5 Why analysis has never been easier. Use the template below to get started.

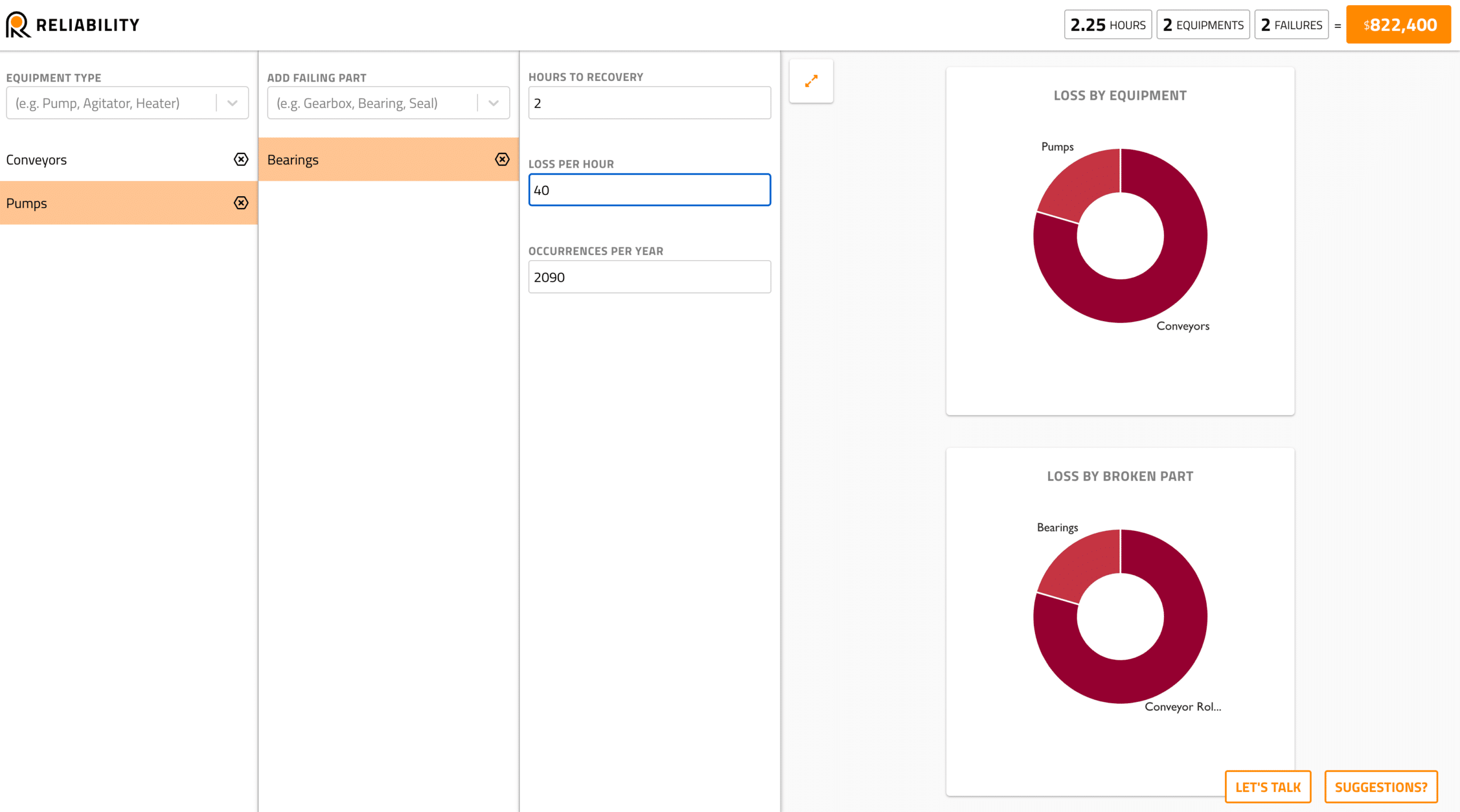

Root Cause Analysis Tool

Basic Failure Analysis

EasyRCA is more than a 5 Whys template. It's a solution for conducting any type of root cause analysis faster and better.

Tool

Root Cause Analysis Training

RCA Templates

Root Cause Analysis Template

From fishbone root cause analysis templates, to 5 Whys, to PROACT®, EasyRCA software has every rca template that you need.

Access Templates

Templates Details

Reliability Articles

5 Root Cause Analysis Examples That Shed Light on Complex Issues

Reading Time: 7 minutes With over two decades in business – spanning strategy consulting, tech startups, and executive leadership – I am committed to helping your organization thrive. At

Root Cause Analysis with 5 Whys Technique (With Examples)

Reading Time: 7 minutes With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive. At

What Is Fault Tree Analysis (FTA)? Definition & Examples

Reading Time: 7 minutes With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive. At

Guide to Failure Mode and Effects Analysis (FMEA)

Reading Time: 7 minutes With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive. At

7 Powerful Root Cause Analysis Tools and Techniques

Reading Time: 5 minutes With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive. At

Understanding Failure Mechanisms and Components

Reading Time: 5 minutes Understanding failure mechanisms and components is a critical aspect of reliability engineering, manufacturing, and maintenance across various industries. Whether you’re dealing with machinery, electronic devices,